Keep Your AC Unit Running Longer and More Efficiently

Spring has officially kicked off, and with warmer weather just around the corner it’s important to ensure your equipment is ready for this change in seasonality. AC units will begin to be turned on once temperatures soar above 60-degrees causing a rush of current to your equipment. To reduce this initial inrush of current to your motor at start-up it is recommended that a soft start be put in place. This will allow your equipment not only to operate more efficiently, but it will also minimize stress, as it gradually ramps up the voltage to the run winding. Applying this low cost “insurance policy” reduced wear and team overtime, increasing the life expectancy of your AC unit.

What is a Soft Start?

A soft start is a device used with alternating current motors to temporarily reduce the startup current of the motor by reducing torque, which aids the motor when starting from a locked rotor condition and improving motor efficiency.

During this process, the input voltage is ramped up slowly, which allows the motor to start with less stress, providing a much quieter startup.

How Does a Soft Start Work?

ICM Controls, a leading, domestic electronics manufacturing company specializing in electronic controls company invented to ICM870, a leading soft start in the industry. The ICM870 soft start includes internal pulse protection, an internal start capacitor, and internal start relay, over current protection and over voltage protection.

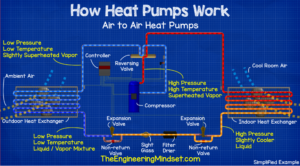

In the same circuit, there is a start/bypass relay, which is vital for a full voltage resumption across the induction motor once it gets to a fully rated speed.

When powering up your unit, silicon-controls rectifiers (SCR)/thyristors activate, restricting the voltage and then relax as the unit reaches full power. This keeps the motor’s head down and reduces overall strain.

Selecting the Right Soft Start

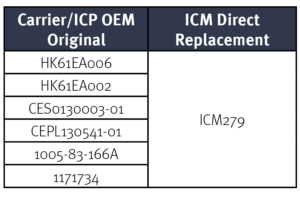

Refer to your service panel or user manual to determine your actual RLA rating:

- ICM870-9A: For use with a compressor load amp rating (RLA) of up to a maximum of 9A

- ICM870-16A: For use with a compressor load amp rating of 9.1-16A maximum

- ICM870-32A: For use with a compressor load amp rating pf 16.1-32A maximum

ICM870 Series

The ICM870 series soft starts ARE compatible with 2-stage HVAC units. If your 2-stage unit has two compressors, you will need two ICM870 units. The ICM870 Soft Start is intended for residential, commercial, RV & marine applications. The ICM870 integrates compressor or motor in-rush current over startup time, thus reducing peak current demand on a power supply source by up to 70%. Effectively reducing power draw to the A/C, the ICM870 utilizes a built-in self-learning algorithm to deliver the optimal in-rush current per application. The ICM870 will monitor system health including voltage, current, compressor startup and integrity. Upon a fault condition, it will halt operation and initiate a 3-minute anti-short cycle routine while providing diagnostic fault information by means of an LED indicator.

Key Features & Benefits:

- Reduces in-rush current/draw necessary at startup by up to 70%

- Prolong the life of the A/C by reducing excessive torque, wear and tear

- Built-in dynamic start delay

- Reduce loud noises, light flickering, and breaker trips

- Built-in self-learning algorithm

- Over-current protection

- Over/under voltage monitoring

- Built-in start capacitor

- LED fault indicators

- Ultrasonic sealed tamper-proof enclosure

- Installation hardware is included

Supporting Documentation: